Spherical bearings are designed to operate — and correct — directional misalignments. These self-aligning thrust bearings are built to accommodate extreme thrust loads. The raceways are inclined to the bearing’s axis, so they can also handle radial loads up to 50% of the thrust load. When the shaft they support takes consistent shocks, consider double row bearings that can realign the bearing to the shaft.

Spherical Roller Thrust Bearings

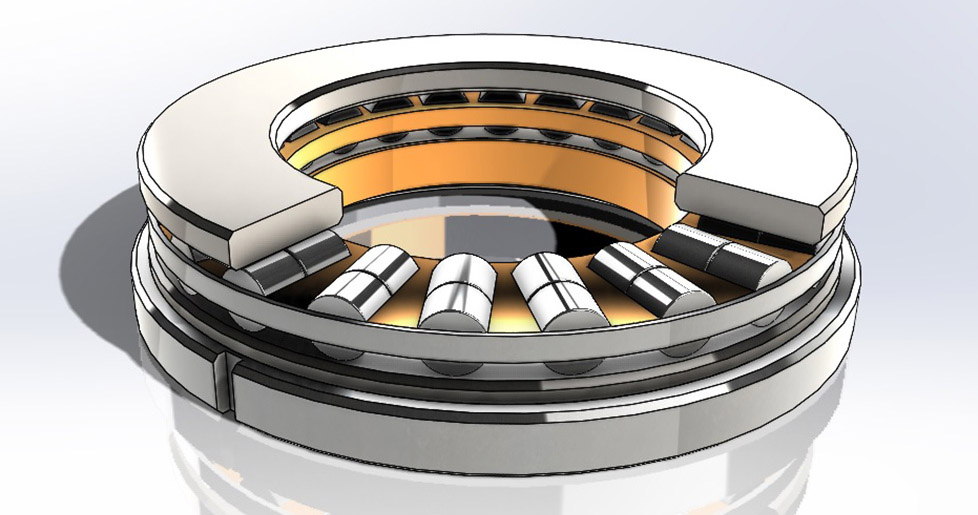

Cylindrical Roller Thrust Bearings

Cylindrical roller thrust bearings are designed to support high axial loads that are parallel to the shaft. They are best used for applications that require low friction at high speeds. They have no radial load carrying capacity. Common applications are extruders, service pumps, sludge/water separation presses, and injection molding equipment to name a few.

Ball Thrust Bearings

Ball thrust bearings are when a thrust force or axial force is parallel to the axis of rotation. We inventory the light-duty, single-direction ball thrust varieties for our distributors, and we are sought for Scheerer’s angular contact ball thrust bearings that can handle both radial and thrust loads. Our grooved race systems are designed for higher load capacities found in electric motors, pumps, and other high-speed applications. Flat race systems are also available for bearings that require minimal space at slower speeds.

Tapered Roller Thrust Bearings

Scheerer manufactures both single and bi-directional tapered roller thrust bearings. This category of bearing is designed specifically to carry axial loads with no radial load capacity. Components include two washers: a shaft washer, and a housing washer plus a removable roller and cage assembly.

Self-Aligning Thrust Bearings

Innovative High-performance Thrust Bearings

Scheerer Bearing manufactures both Ball Thrust Bearings and Roller Thrust Bearings. These bearings operate where a force or axial force is parallel to the axis of rotation. We inventory the light duty, single direction ball thrust varieties for our distributors, and we are best known for the angular contact ball thrust bearings that handle both radial and thrust loads.

Our grooved race systems are designed for higher load capacities found in electric motors, pumps, and other high-speed applications. Flat race systems are also available for bearings that require minimal space at slower speeds.

ID Range:

50.8 mm to 609.6 mm (2 in. to 24 in.)

Applications:

- Construction wheeled equipment

- Drilling equipment

- Lifting equipment

- Power generation gearboxes

Design Attributes:

- Bottom washer design makes bearing adaptable to initial misalignment.

- Overlapping roller paths prevent “grooving” of races and prolong bearing life.

- Minor radial displacement of the races does not affect the operation of a TPS bearing, resulting in manufacturing economies and easy installation.

- Simple design is the most economical to purchase and install.

Large Diameter Thrust Bearing Experts

Our large and extra-large thrust bearings start at 120 mm ID through 2500 mm OD.

Scheerer Bearing manufactures large diameter thrust bearings in standard configurations including ball, cylindrical roller, tapered roller and spherical roller.

We manufacture all standard formats from all major manufacturers. We also manufacture custom solutions for specialty applications.

Variants & Options

- Ball Thrust Bearings

- Cylindrical Roller Thrust Bearings

- Tapered Roller Thrust Bearings

- Spherical Roller Thrust Bearings

- Self-Aligning

- Bearing Customization

PARTNER WITH SCHEERER.

PERFORM BETTER.

Call Scheerer direct: (800) 443-5252

Get a Preliminary Estimate.

Send us Your Specifications.

- Inch or Metric

- Bore Dimensions (d)

- Outer Diameter (D)

- Width of the Bearing (B)

- Required Load Capacity (C & Co)

Our engineering team routinely reviews proposed CAD designs from customers. We are available to share insights you may not have considered.

Contact Scheerer Bearing Direct at (800) 443-5252