Industrial bearings for machinery, heavy equipment, energy, materials

processing and manufacturing

Scheerer’s tapered roller bearings are designed for the most challenging operational environments. Our bearings are at work right now in marine and coastal operations, extreme hot and cold temperatures, high-speed processing, systems with dynamic load changes and more.

Tapered roller bearings can handle both radial and axial loads, and they support hub assemblies found in vehicles, gearboxes, and heavy equipment that require a shaft. Oil rigs, mining operations, and large construction vehicles rely heavily on taper roller bearings. In many cases, large wheel assemblies found on big trucks use tapered roller bearings that are assembled in pairs. While there are numerous applications, rest assured that Scheerer Bearing is the only supplier you’ll need.

Multi-row Bearings for Steel Mills and Materials Processing

As rotor diameters increase, confidence in your bearings becomes even more critical. We offer a full line of bearings for wind turbines, gearboxes, slewing ring bearings and main shaft bearings. We also specialize in tapered roller thrust bearings for a number of applications.

Scheerer Bearing is committed to supporting renewable energy including wind turbines.

Your Partner in Innovation

Bearings in wind turbines operate in extraordinary operational environments where extremes in temperature, load fluctuation, corrosion exposure and more create unique challenges for engineers and wind turbine designers. Scheerer Bearing partners with OEMs and turbine farm managers to improve performance, durability, bearing maintenance access and lubricant optimization.

Custom Tapered Bearing Design

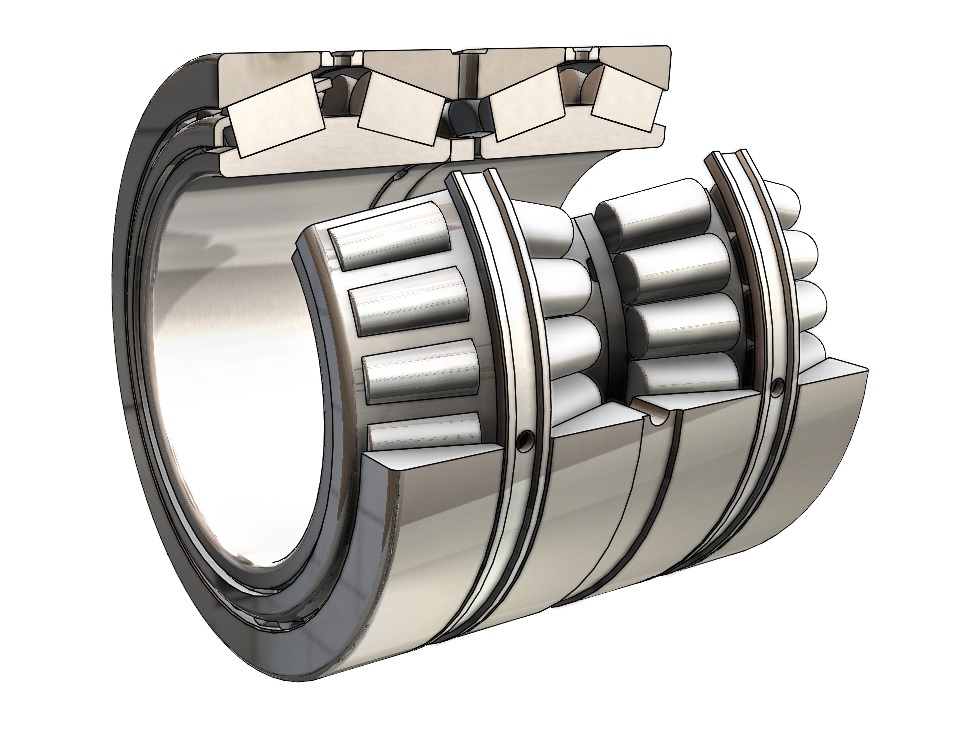

Scheerer Bearing produces all of the major tapered roller bearing lines, from standard single row cup cone configurations (TS), to double row two piece inner or outer ring designs (TDO, TDI and TDS), to tapered thrust bearings (TT and VFT). In addition, Scheerer can provide custom sizes and designs, including non-standard cages, custom clearances or preloads, and installation features like flanges, extended components for seals, and anti rotation elements. From 3” ID to 62” OD, we’ve got you covered.

Our team can review your CAD designs and offer insights you may not have considered.

To find out how Scheerer Bearing can help you achieve better performance, contact us at (800) 443-5252 or submit our custom bearing specification’s form to start a conversation.

PARTNER WITH SCHEERER.

PERFORM BETTER.

Call Scheerer direct: (800) 443-5252

Get a Preliminary Estimate.

Send us Your Specifications.

- Inch or Metric

- Any special designs and variants (NU, NCF, RAD, etc.)

- Bore Dimensions (d)

- Outer Diameter (D)

- Width of the Bearing (B)

- Required Load Capacity (C & Co)

Our engineering team routinely reviews proposed CAD designs from customers. We are available to share insights you may not have considered.

Design and Manufacturing of Tapered Bearings in all Standard Configurations

Scheerer Bearing manufactures and reconditions large industrial bearings of all varieties used across heavy industry, heavy equipment manufacturers and other large format commercial applications. Our manufacturing capabilities enable us to design and produce tapered bearings up to 100” O.D. and bore sizes over 5”/127mm and up to 85”/2159mm.

- Inch Single Row

- Metric Single Row

- Inch Double Row

- Metric Double Row

- Four Row

- Tapered Roller

- Integrated Bearing Assemblies

Contact Scheerer Bearing Direct at (800) 443-5252