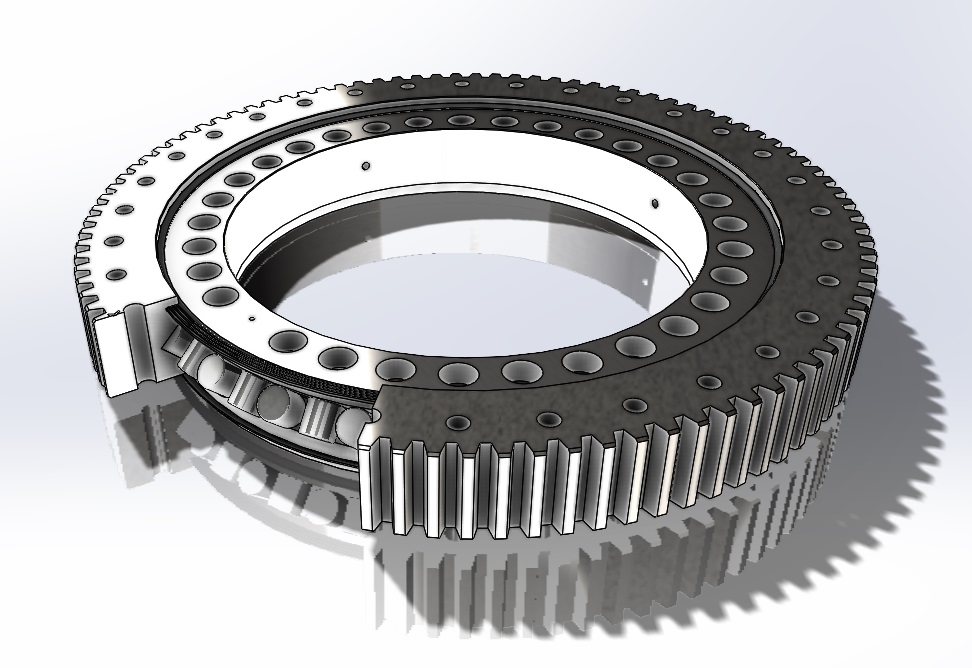

Scheerer’s slewing ring bearings are machined and manufactured from the highest quality materials. They are engineered to withstand maximum allowable static and dynamic axial, radial, and moment loads while providing the optimum combination of weight, performance, size, and sustainability.

What slewing ring bearing configuration is right for your application? Scheerer can help.

- Four point Ball or Cross Roller

- Single, double, and triple row configurations

- Geared inner or outer rings

- Sizes from 4” (100mm) to 100” (2540mm) bores.

Slewing Ring Bearings for Critical Equipment

Excavator Bearings

Bearings for Amusement Park Rides

Crane Bearings

Robotics for Material Handling

Forestry Handling Equipment

Conveyor System Bearings

Rotary Table Bearings

Marine Environments

Wind Turbines

Medical Equipment (CT/MRI)

Custom Features Available

Rectangular cross sections for mounting and lubrication customization.

Low profile cross sections, when space is at a premium.

Sealing features for long lifecycles in the harshest environments.

Slewing Ring and Industrial Turntable Bearings

Slewing ring and industrial turntable bearings are designed for 360 degree rotation under radial, axial and moment loads. Often face-mounted using bolt hole patterns, these unique bearings can support rotation from external components, or can be used as the primary drive feature through an outer or inner ring gear. These bearings come in a wide variety of sizes and configurations, from a 5” ID all the way up through a 150”+ OD, and can provide the perfect bearing solution in many different

applications. Scheerer’s ability to customize these slewing ring bearings is unique, in that they can be used to fill multiple rolls and serve several functions. In addition to offering interchanges for all of the standard series slewing ring in the industry, Scheerer bearing routinely works directly with OEM manufacturers to design application specific units, and can even provide replacements for discontinued legacy slewing ring bearings.’

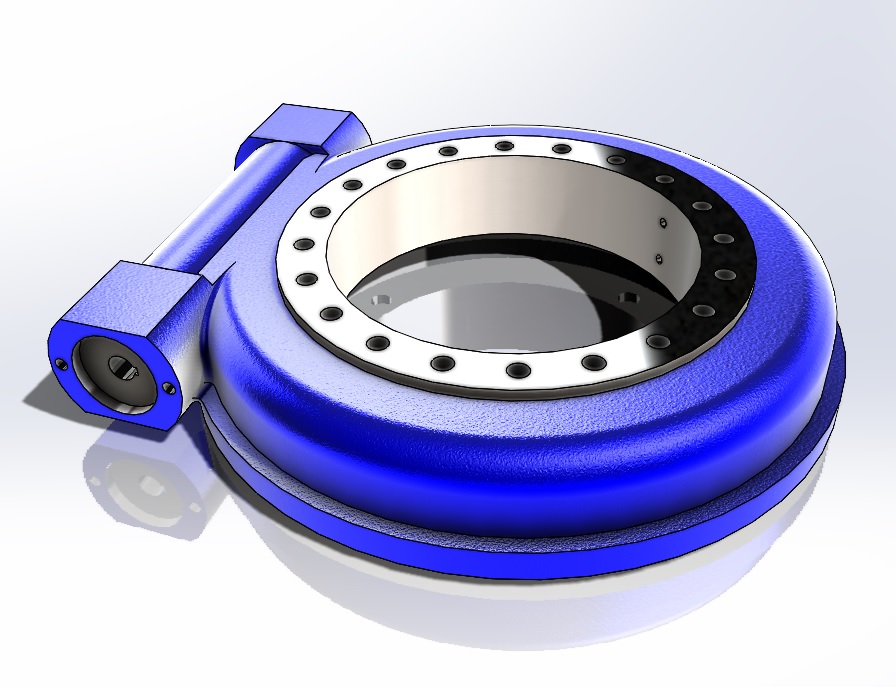

Slewing Drive Units – Strength and Precision

Slewing drives come in a variety of formats but are primarily based on worm gear mechanisms. Worm gears offer precision and smooth rotation under substantial loads. The combination of a slewing drive / bearing combination reduces the speed but multiplies its torque, making them ideal for applications that require both critical load-holding strength and rotational torque all while providing high-precision movement.

Features / Advantages

- Compact & Easy to Install

- Extreme Diameter

- Single/Dual worm

- Single/Double row bearing

- IP55/IP65 sealing

- Clearance (backlash) controlled

- Open/Enclosed housing

- Self-locking gearset

Custom Slewing Bearing Design

The right configuration and the right materials can improve operational performance, longevity and reliability. Our team can help develop or evaluate proposed designs. We can often offer insights you may not have considered.

To find out how Scheerer Bearing can help you achieve better performance, contact us at (800) 443-5252 or submit our custom bearing specification’s form to start a conversation.

When planning a new design, we take a lot of things into consideration. This list represents some of the key elements of a design specification.

Features & Performance Characteristics

High load carrying capacity

High stiffness for rigid bearing application

Low friction

Long service life

Surface protection and corrosion resistance

Optional Features

Driving mechanism

Control devices

Lubrication systems

Monitoring systems

Sealing cassettes

PARTNER WITH SCHEERER.

PERFORM BETTER.

Call Scheerer direct: (800) 443-5252

Get a Preliminary Estimate.

Send us Your Specifications.

- Inch or Metric

- Any special designs and variants (NU, NCF, RAD, etc.)

- Bore Dimensions (d)

- Outer Diameter (D)

- Width of the Bearing (B)

- Required Load Capacity (C & Co)

Our engineering team routinely reviews proposed CAD designs from customers. We are available to share insights you may not have considered.

Contact Scheerer Bearing Direct at (800) 443-5252