Bearings for Mining, Aggregate and Material Processing

Designed for Work in the Toughest Environments

Industrial mining and mineral processing is tough on all types of equipment:

Scheerer Bearing manufactures bearings for the mining, excavating, and mineral process industries that perform exceptionally well under severe operating conditions.

Superior Performance for the Most Demanding Industrial Applications.

Get Our Competitive Advantage.

Bearings are designed to take a beating in tough environments. With proper design and maintenance, your corrugator equipment bearings can ensure consistent high-performance in high-stress environments.

Companies across the paper industry seek long-term value through precision engineering. Scheerer provides that kind of detailed engineering to manufacturers and processing companies throughout the corrugated, paper, pulp and board manufacturing sector.

Partner with Scheerer.

Perform Better.

Call Scheerer direct: 215-443-5252

Get a Preliminary Estimate.

Send us Your Specifications.

- Imperial or Metric

- Any special designs and variants (NU, NCF, RAD, etc.)

- Bore Dimensions (d)

- Outer Diameter (D)

- Width of the Bearing (B)

- Required Load Capacity (C & Co)

Our engineering team routinely reviews proposed CAD designs from customers. We are available to share insights you may not have considered.

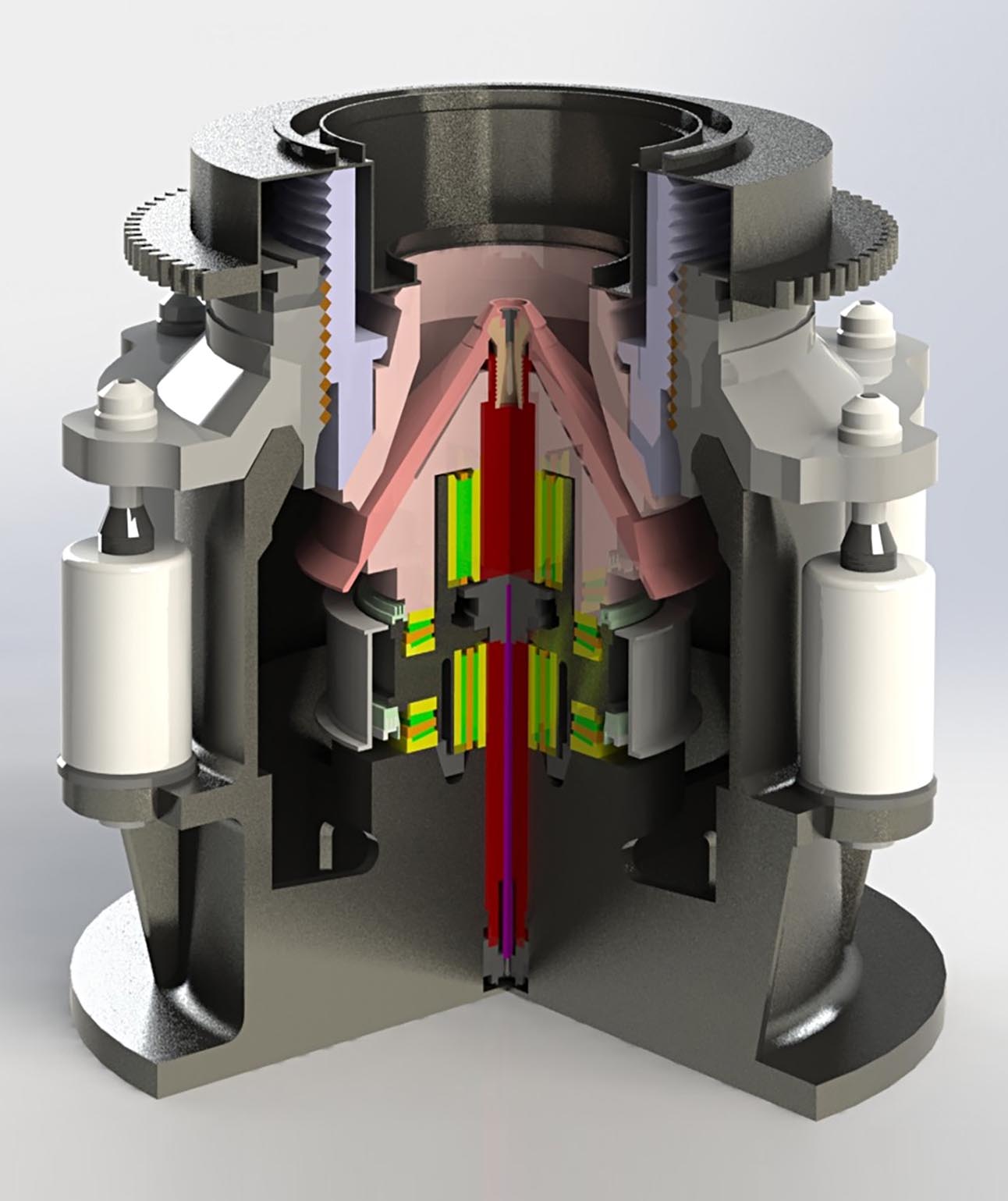

Heavy-Duty Bearings for the Mining, Cement and Aggregate Materials Industry

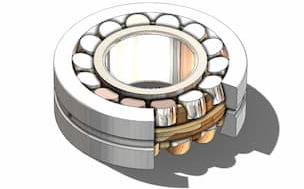

Double Row Spherical Roller Bearings

Spherical roller bearings are capable of carrying heavy loads in both radial and axial directions. Due to their self-aligning design, they are capable of adjusting for angular misalignment between inner and outer ring without any effect on bearing performance. They are available in a variety of standard and specialized designs, including cylindrical or tapered bore options.

If you have damaged bearings, you can send them to Scheerer Bearing for a thorough evaluation for bearing repair or reverse engineering eligibility.

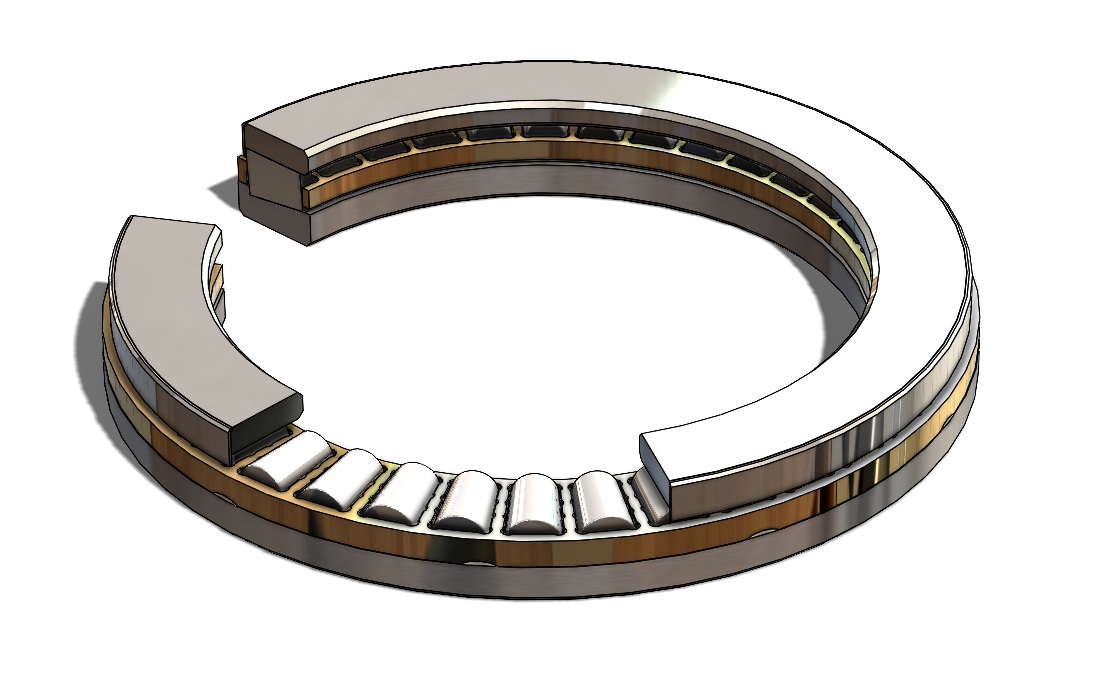

Roller Thrust Bearings – Heavy Duty

Roller thrust bearings have the highest possible axial load capacity for a envelope cross section, making them capable of operating in shock prone applications with high safety margins. They provide rigid bearing support, offer high operational reliability and typically boast long service lifecycles.

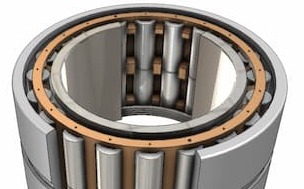

Conveyor Bearings for Mining and Material Processing

Conveyors use full complement cylindrical roller bearings to provide the highest possible radial load capacities by maximizing the number of rollers. Conveyor bearings are designed with the maximum number of rollers for very heavy radial loads; this design incorporates a low sectional height as compared to its width, giving you increased equipment reliability with lower installed weight.

Radial Cylindrical Roller Bearings

Cylindrical roller bearings are one of the most widely used types of bearings today. Most are designed to carry heavy radial loads. The smaller, more common single row cylindrical roller bearings are often manufactured in large volumes and Scheerer maintains a healthy inventory. In addition, we also specialize in custom bearings with bore diameters from 2 inches up to 80 inches (50 mm to over 2,000 mm).

Contact Scheerer Bearing Direct at (800) 443-5252