Ball bearings are highly versatile. There are numerous configurations and design variants, supporting many types of applications in almost every major industry.

Ball bearing manufacturers typically produce standard sizes, satisfying common catalog ball bearing lines. Scheerer is no exception. We stock, and are ready to ship all of the common metric and inch series ball bearings.

Custom Bearing Configurations

In addition to standard bearing lines, we regularly design and manufacture special bearing sizes and custom configurations. Regardless of quantity, Scheerer can produce a ball bearing that is right for your application, be it a new prototype with special requirements or a decades old piece of equipment that has been refurbished to new dimensions, and at prices and lead times that rival the most common of bearings.

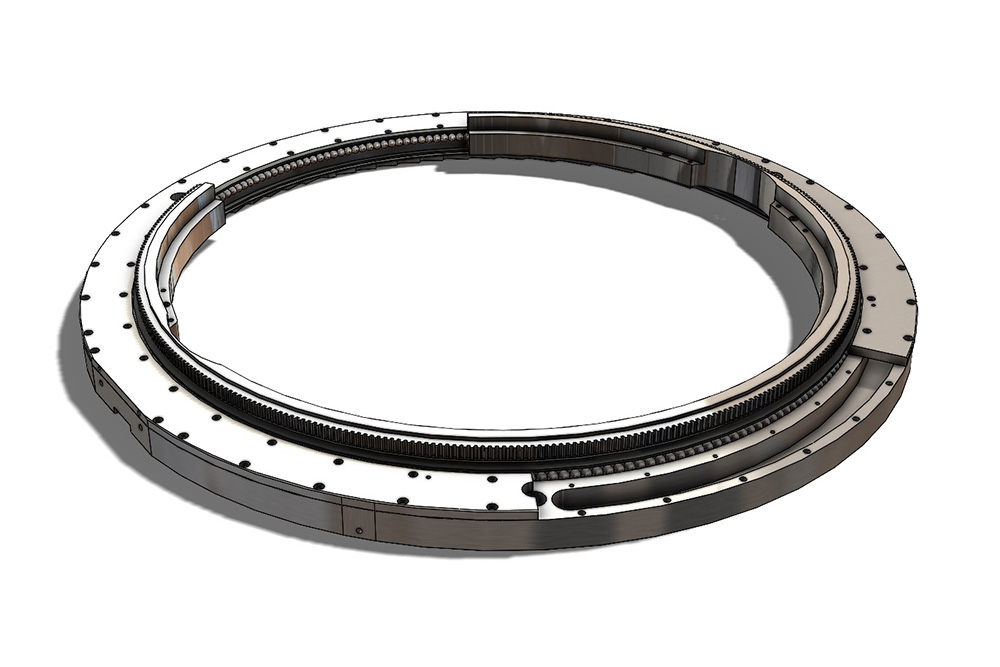

Large- bore Bearing Specialists

Scheerer Bearing routinely designs and manufactures several types of larger bore specialty bearings that many ball bearing manufacturers in the USA and abroad will not produce.

State-of-the-Art Bearing Design & Engineering

Scheerer designs and manufactures custom ball bearings from 1″ bore to 100″ OD.

Custom Ball Bearing Engineering

Unlike other ball bearing manufacturers that focus on mass production, Scheerer works regularly with original equipment manufacturers (OEMs) and bearing designers to create solutions that put form, fit and functionality first. When designing a new piece of equipment or re-engineering an older design for improved functionality, we encourage you to test our expertise and creativity.

Our team can review your CAD designs and offer insights you may not have considered.

To find out how Scheerer Bearing can help you achieve better performance, contact us at (800) 443-5252 or submit our custom bearing specification’s form to start a conversation.

PARTNER WITH SCHEERER.

PERFORM BETTER.

Call Scheerer direct: (800) 443-5252

Get a Preliminary Estimate.

Send us Your Specifications.

- Inch or Metric

- Any special designs and variants (NU, NCF, RAD, etc.)

- Bore Dimensions (d)

- Outer Diameter (D)

- Width of the Bearing (B)

- Required Load Capacity (C & Co)

Our engineering team routinely reviews proposed CAD designs from customers. We are available to share insights you may not have considered.

Large & Extra-Large Custom Ball Bearings

Scheerer Bearing manufactures in-house and thrives on larger industrial ball bearings used in steel mills, paper mills, wind turbines, industrial gear boxes, and many electric motor applications. Our manufacturing capabilities enable us to design and produce ball bearings with bore sizes over 2″/ 50mm and up to 120” / 3048mm.

85% of our larger single row deep groove ball bearings are produced with brass cages. Scheerer also processes alternate cage materials such as steel, stainless steel, polyamide, or PEEK. Scheerer application engineers will work alongside you, working with operating details such as speed, loading, temperature limits and lubrication type, to help you select the optimum bearing for high maximum efficiency and long life.

Contact Scheerer Bearing Direct at (800) 443-5252