Industrial Bearing Repair and Reconditioning Services

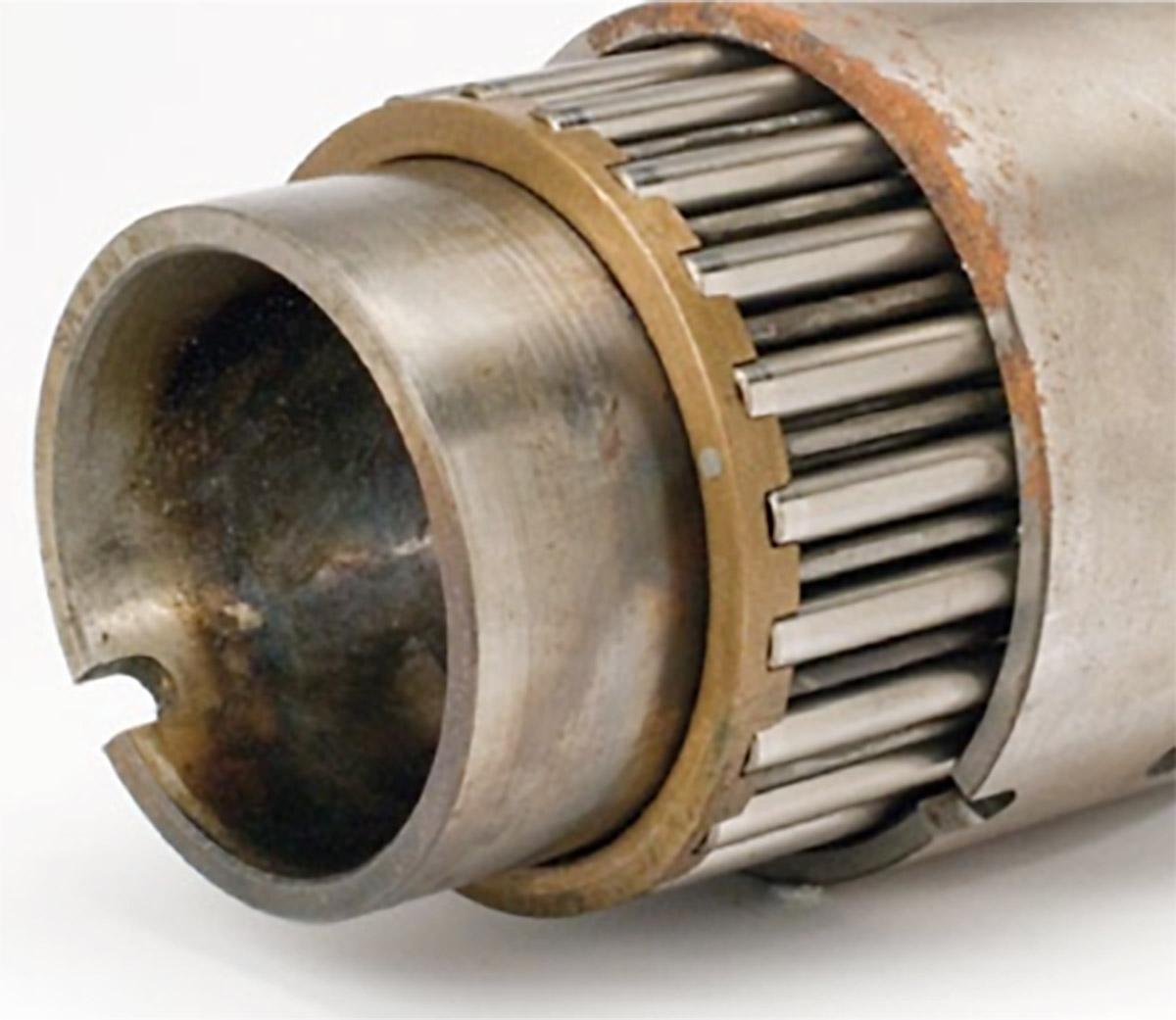

In addition to manufacturing standard and custom industrial bearings for our distributors, Scheerer Bearing has a bearing services department dedicated to repairing damaged bearings and supporting large bearing reconditioning. Bearings used in earthmovers, mining equipment, pulp and paper mills, steel mills, utilities, material handling and industrial production equipment, are prime candidates for reconditioning. Premature failures of heavy industrial bearings directly contribute to higher operating costs. Equipment downtime is very expensive. Rebuilding bearings is a sustainable alternative to purchasing new bearings. We can recondition bearings of every conceivable design ranging from 2” I.D. to 100” O.D. from virtually any manufacturer, to restore original specifications.

Bearing Inspection and Performance Testing

Scheerer provides detailed quotes including price, options, and estimated time to complete your reconditioning project. Our quote enables you to decide whether it is more economical to repair the bearing or to purchase a new bearing.

Upon arrival at our reconditioning and testing facility, bearings undergo a rigorous inspection and functional assessment. Scheerer Bearing uses a detailed rating system to accurately measure the condition and potential of a reconditioned bearing. Our process specifies the parts, labor, and materials needed to restore a bearing to the original manufacturer’s specifications.

Scheerer Bearing Corporation guarantees all refurbished bearings to be free of material and manufacturer defects for one year.

Bring Your Bearings Back to Spec

Bearing Reconditioning Solutions

- All Bearing Types, All Manufacturers

- Size Ranges — from 2″ to 100″

- Planned Reconditioning Programs

- On-Site Inspection

- Bearing Transport and Logistics

- Control Downtime by Design

- 24/7 Emergency Service

Scheerer’s bearing reconditioning services return bearings to their original specifications. This is especially valuable for large bearings where cost savings over a new bearings can be dramatic.

PARTNER WITH SCHEERER.

PERFORM BETTER.

Call Scheerer direct:

215-443-5252

Send us Your Specifications

- Imperial or Metric

- Any special designs and variants (NU, NCF, RAD, etc.)

- Bore Dimensions (d)

- Outer Diameter (D)

- Width of the Bearing (B)

- Required Load Capacity (C & Co)

Email: sales@scheererbearing.com

Fax: 215-443-7513

Phone: 215-443-5252

Reconditioning Facility Address:

Scheerer Bearing – Reconditioning

633 Davisville Road

Willow Grove, PA 19090

Contact Scheerer Bearing Direct at (800) 443-5252